After seeing many nice modifications for the popular Behringer FCB1010 MIDI pedal board I have decided to create one of my own. Unable to find information for a mod with similar cabling i decided to post my findings here. Just to inspire others to create even better mods for this awesome pedal board.

The main purpose of this mod is to provide the FCB with a single cable for two-way Midi and power. I don’t want a million cables on the floor and I was looking for a cable setup that was cheap and the cable should be easily replaceable. I need 4 conductors for Midi and 2 for power, therefore I decided to go for a simple computer UTP cable which has 8 conductors. These cables are cheap and easy to obtain and they come prefab in many different lengths and colors.

There are quite a few phantom power mods out there which require one to use either switches or diode-rectifiers to switch between phantom- or self-powered operation of the FCB. I decided I would never want to have the FCB self-powered and I would just take the power converter from the board. This would make the setup much simpler.

Materials for this project:

Materials for this project:

(all bought from conrad.nl for those in Europe)

| 1x Euro-casing black 150x50x80mm (part# 520616) |

€ 2,85

|

| 2x Neutrik RJ45 chassis bus NE 8 FDV (part# 746738) |

€ 12,54

|

| 1x CAT 5E cable F/UTP 5m (part# 990581) |

€ 13,99

|

|

|

| 1x 3m 5pin midi cable I had laying around |

€ 6,79

|

| Tapered drill |

|

| Some shrink tubing |

|

| Soldering supplies and tools |

|

|

|

| Total |

€ 36,17

|

(€ 36,17 is roughly 45 USD)

Ripping out the power converter

As mentioned earlier I decided to use the FCB1010’s own power converter and relocate it into to an external casing for phantom power. So first step was to clip the wires on the power converter and take it out of the FCB. Make sure to clip the yellow wires, leading to the circuit board, halfway so you can have enough room to solder the clipped ends to the RJ45 connectors later on. Removing the power converter looks easier said than done. In the end I had to push out the main power switch and temporarily remove a glued led before I was able to do so.

Be safe and properly seal the wires from the old main power connector, so you don’t get electrocuted when someone accidentally hooks up a power cable to the old connector.

Relocating the power converter to its new home

The power converter in my unit has three input wires and two output wires (as seen below). But like the original setup I only used the red and black input wires. Since this casing would be permanently installed in my flight case I opted to just make direct cables for the connections that would stay connected permanently: Power to my power conditioner and Midi to my AxeFX. Therefore I just soldered a power cable directly to the two input wires of the power converter.

The two yellow output wires from the power converter are also alternating current (AC). Since the current alternates we don’t have to worry about positive and negative and we can just solder the two wires to two of the pins on the RJ45 chassis bus. I used shrink tubing to tidy everything up.

Midi in the external case

After I made two holes for the midi cables I cut the 3 meter midi cable in pieces so that I ended up with two midi connectors and a piece of wire of the length I desired. After stripping the wires I soldered the 4 and 5 pin wires to 4 pins on the RJ45 chassis bus. Notice how I made a knot in the power and midi cables, preventing tension on the soldering if one would pull on those cables.

A few tips on soldering: 1/ If you want to use shrink tubing, put over the wire before soldering 😉

2/ Pre solder some tin on the wire and pins before making the actual solder, this gives you a free hand to hold the wires in place.

Drilling the FCB1010

As seen in the photo below I located the RJ45 bus next to the external switch jacks. This location gives you a lot of room to solder your wires and still be close to the midi connectors on the FCB. Disconnect the plug for the external switch 1&2 from the FCB circuit board to give yourself a little more room to operate.

Drilling the hole for the bus proved to be the hardest part of the project. After destroying a few of my Dremel bits I decided to get a tapered drill to finish the job. That was really the easiest way to get the hole to the size I wanted.

A tapered drill

Soldering the FCB RJ45

Remember we cut the yellow power wires in half at the start of the project when we took out the power converter? Now we should have more than enough wire to reach the RJ45 bus. Find the pins you used for the power and solder the yellow wires to them. Again, it’s alternating current, so order doesn’t matter. Don’t forget your shrink tubing.

Next up is the soldering of the Midi wires. We’re just going to solder the wires from the RJ45 bus to the original midi input and outputs of the FCB. At this moment it doesn’t really matter what pair we solder to which midi port, just as long as you solder the pairs to the 4 and 5 pins. On the connectors it’s the pin 2 and 4 counted from left to right, or another way to describe: don’t solder on the middle and outer pins. 😉 Keep in mind that unlike the power cables, the Midi is directed so polarity does matter. In my case I had to de-solder the wires from the original midi connectors and swap them, because the FCB wouldn’t work.

Don’t forget to reconnect your external switch 1&2 connector if you want to use them.

The end (result)

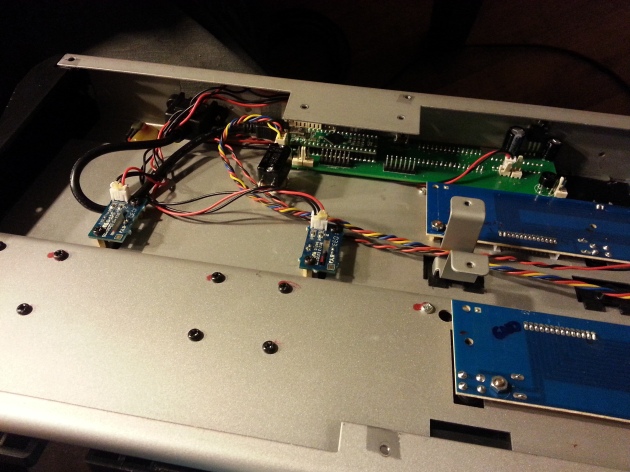

The end result is that I have a tidy little box that I can just leave permanently connected in my flight case and when I want to hook up my FCB I just have a single cable to plug in.

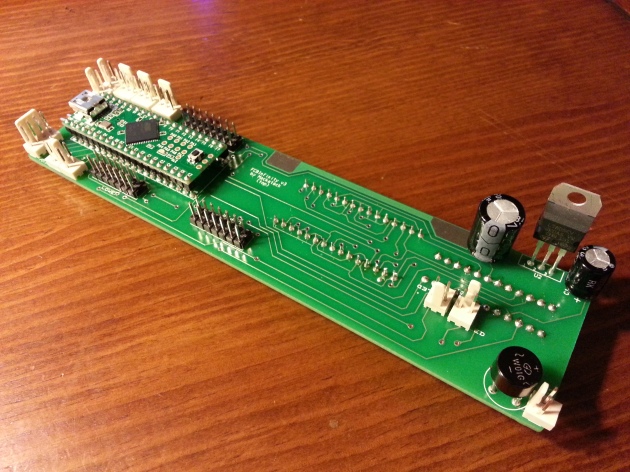

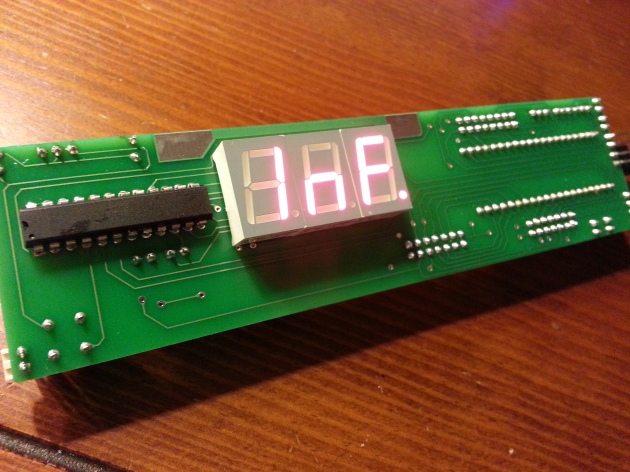

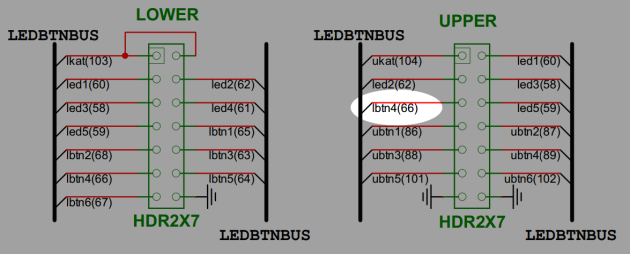

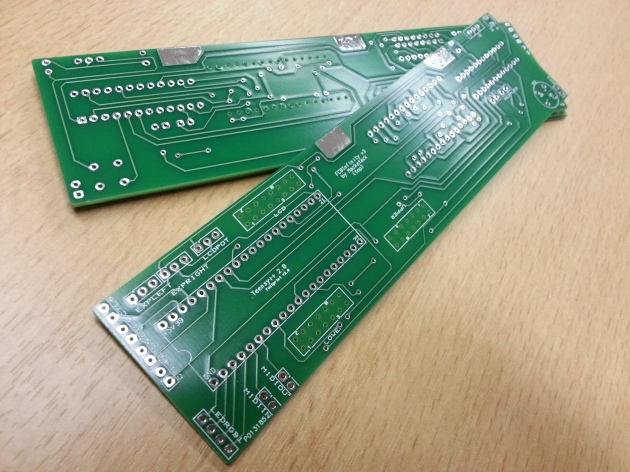

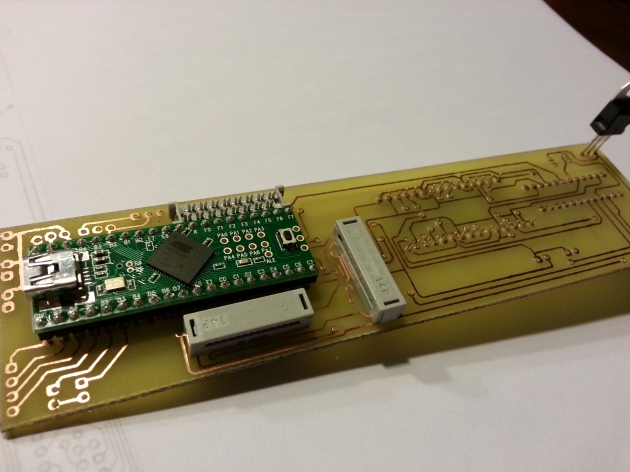

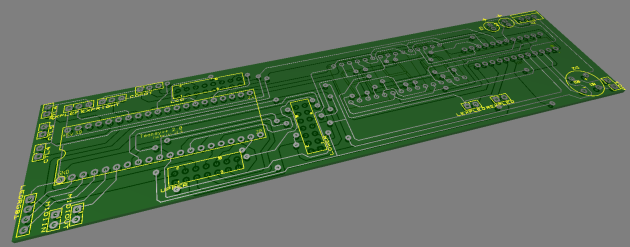

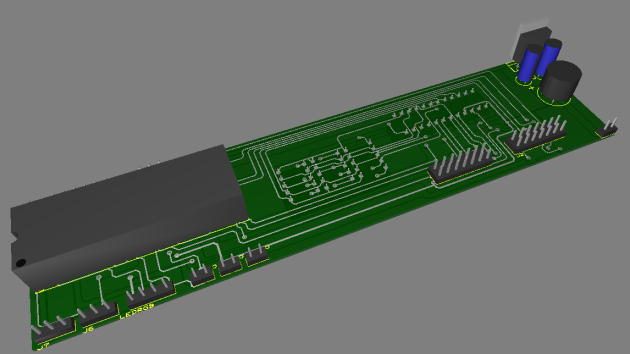

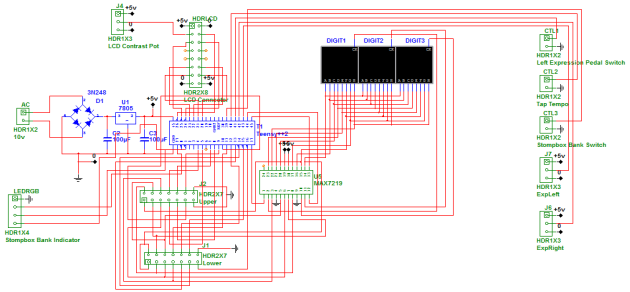

I think my next project is to add a LCD and a couple of extra switches to the FCB using a Teensy development board and have the Teensy board also communicate over Midi. This would allow me to show the AxeFX tuner and patch names on the FCB. I might go crazy and completely gut the FCB and have the Teensy handle all the buttons. End result: (midi) world domination, but then this would no longer be a FCB1010, but FCB-Infinity or whatever. I’ll make sure to split up those projects in two steps, so I can show you how to have the FCB communicate with AxeFX with minimal changes to the FCB.

I hope you enjoyed!

FCBInfinity GitHub updates

FCBInfinity GitHub updates

Recent Comments